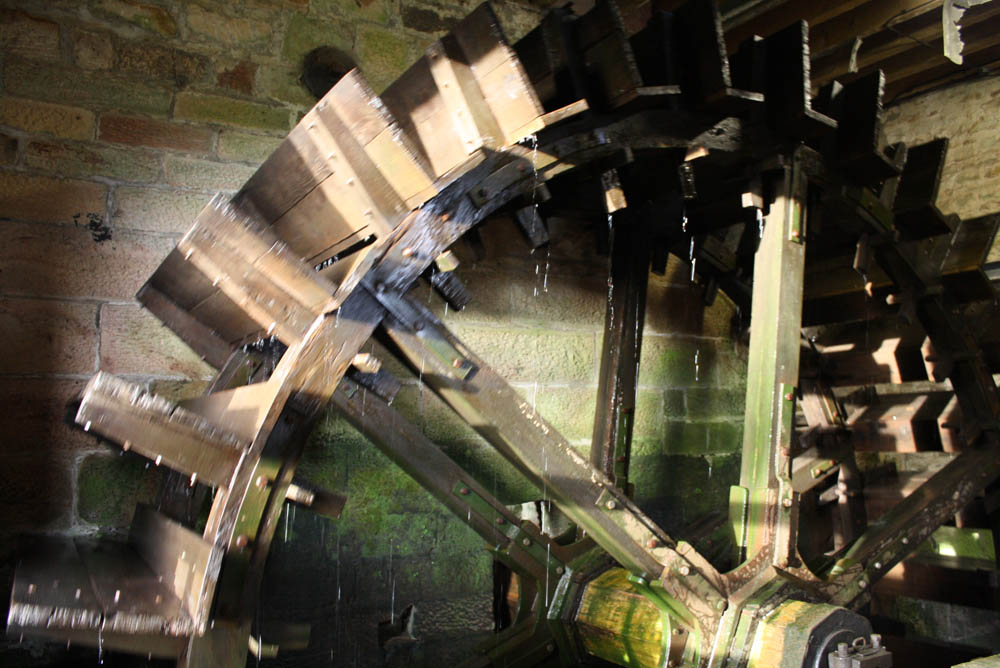

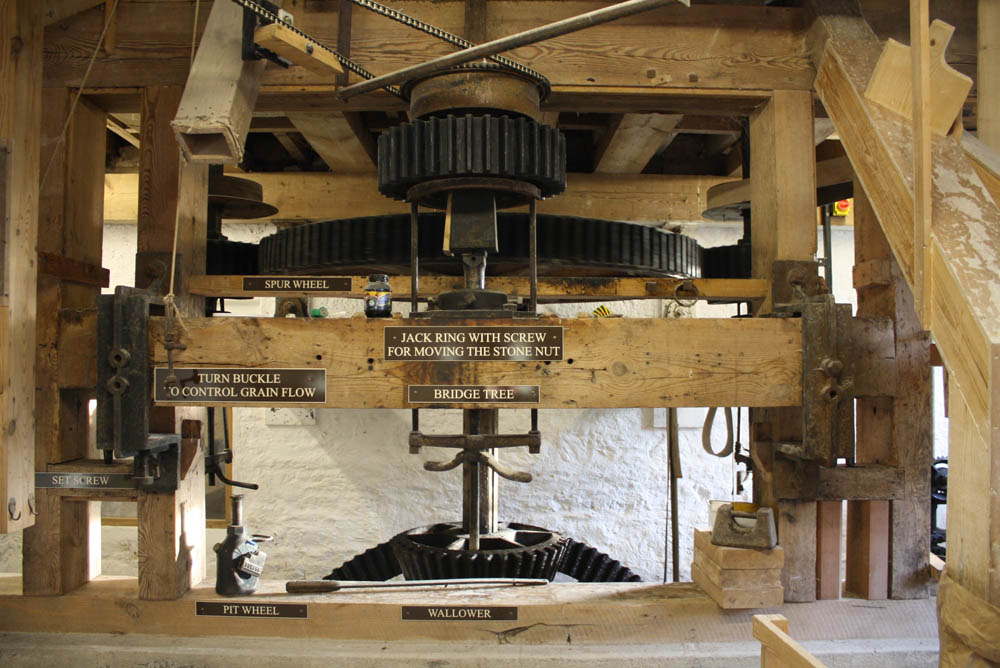

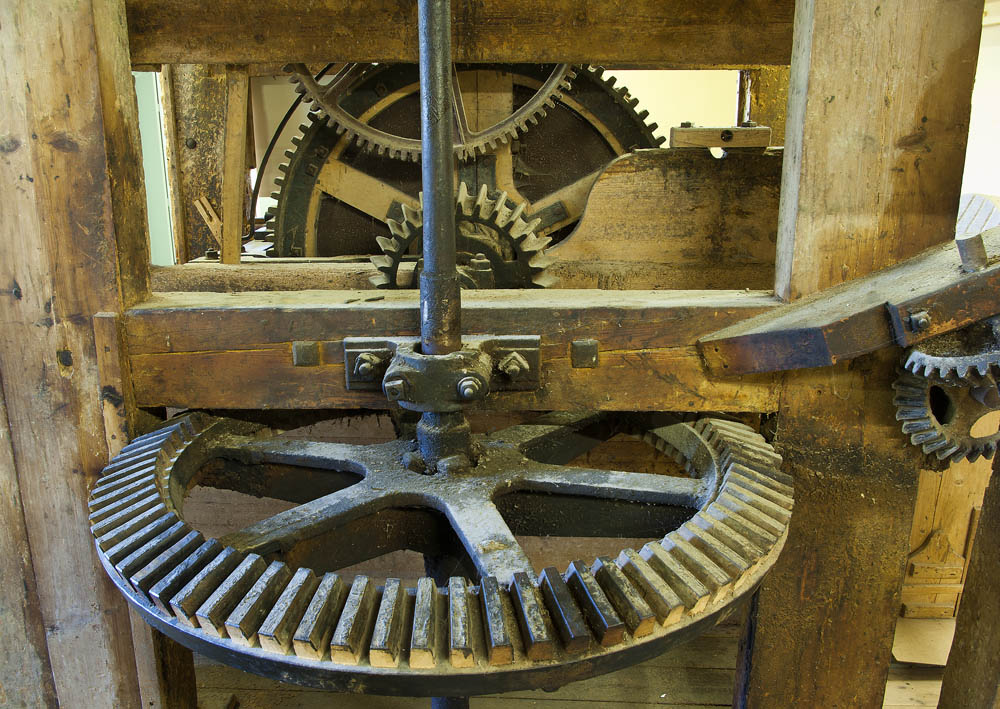

Heatherslaw Corn Mill is actually two water mills under one roof, each with its separate water wheel and mill race. Each mill has three pairs of horizontal grinding stones for making flour or meal and a vertical stone for pearl barley polishing. The power comes in from the undershot water wheel at the bottom of the building and is transmitted by gears and shafts to the top.

It is the job of the miller to balance the control of the sluice gate (to vary the amount of water pushing the wheel around), the gap between the millstones and the flow of grain between them. Getting this balance right means making the highest quality of flour, getting it wrong risks damaging the stones and even causing a dust explosion.

The grain is then tipped into hoppers that bring it down to the millstones. Two of the pairs of millstones you can see are made of French Burr, one of the hardest natural stones. These are used to mill wheat into flour. The others are made of Derbyshire Peak gritstone. The lower stones of a pair (bedstones) do not move – it is the top (runner) stone that revolves. After the grain has been turned into flour (known as meal) it leaves the stones and drops down a chute to a sack on the lower floor. After this it can be weighed and sold either to local shops or bakeries or direct to customers in the mill shop.

Pearl barley was milled here until the 1950s and the machinery used can be seen in the Lower Mill Museum. Barley grains were fed into a hopper which took a measured load into a vertical millstone arrangement, with the vertical stone and outer casing rotating at different speeds – efficiently de-husking and polishing the pearl barley. It was then put through a ‘dresser’ which mechanically separated the dust and husks from the good clean grains. After this final process the product could be bagged.

switch website